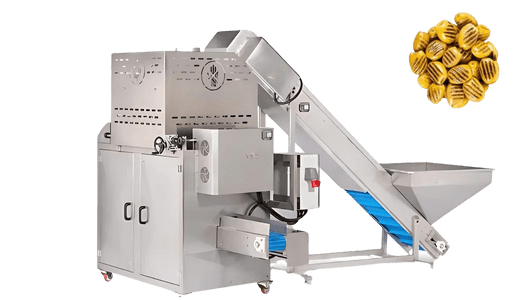

8 Blade Olive Pitting, Pit Removal Machine

This machine is designed to remove the pits from various types of olives and is manufactured with 8 blades. It is capable of processing up to 1400 olives per minute. The machine features electronic speed control, allowing it to operate at the desired speed. It is constructed using 100% stainless steel and high-quality engineering plastics. Thanks to its lubrication system, wear is minimized, ensuring a healthy and long-lasting working environment.

View Machine

12 Blade Olive Pit Removal Machine

This machine is designed to remove the pits from various types of olives and is manufactured with 8 blades. It is capable of processing up to 1400 olives per minute. The machine features electronic speed control, allowing it to operate at the desired speed. It is constructed using 100% stainless steel and high-quality engineering plastics. Thanks to its lubrication system, wear is minimized, ensuring a healthy and long-lasting working environment.

View Machine

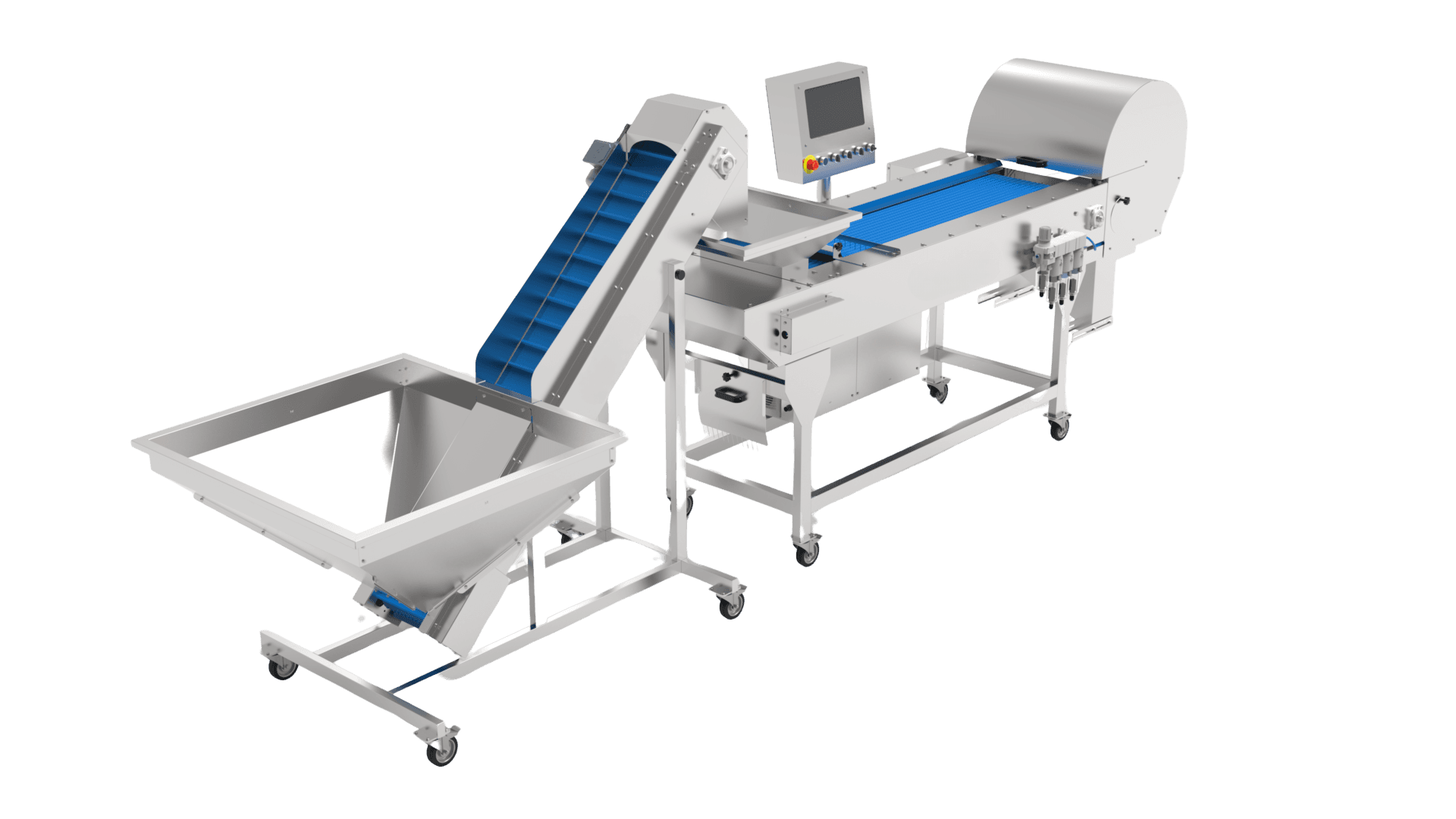

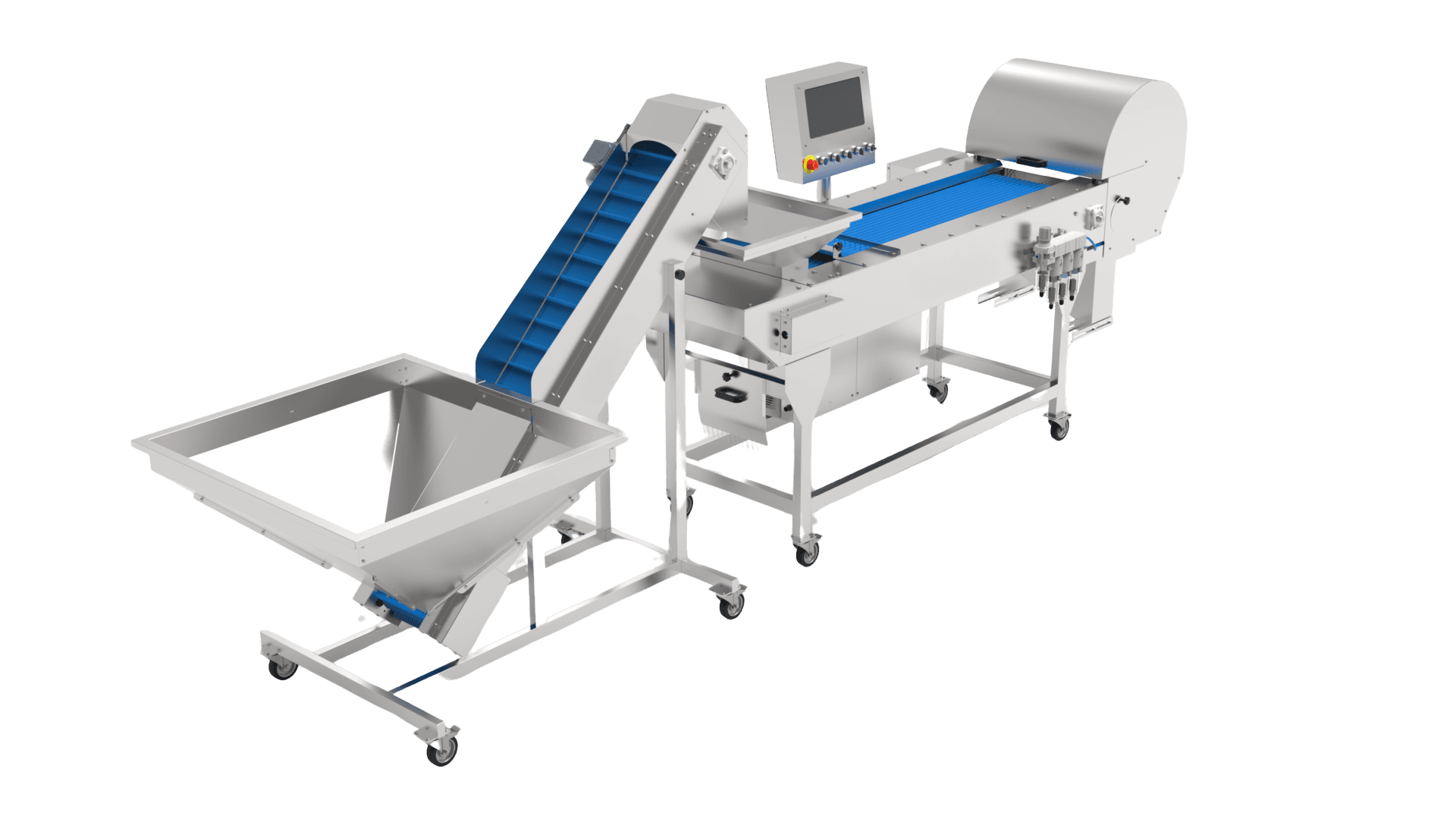

CH16 Olive Color Sorting Machine

This machine is designed for designed to separate olives of different colors. It has features such as bands and stainless products in accordance with food regulations, Computerized control system, Camera systems that take photos of olives from one direction, 2 outputs. Automatic color recognition with Artificial Intelligence software.

View Machine

CH30 Olive Color Sorting Machine

This machine is designed for designed to separate olives of different colors. It has features such as bands and stainless products in accordance with food regulations, Computerized control system, Camera systems that take photos of olives from one direction, 2 outputs. Automatic color recognition with Artificial Intelligence software.

View Machine

Dragon 600 Grilling Machine

Speed Adjustable Automatic Feeding Band LPG or LNG operated Cooling System on bearings for long term operation under heating Automatic fire ignition system. Up to 600kg / hour capacity W: 900 mm x L: 1200 mm x H: 1650 mm Adjustable cylinder gaps according to the product sizes (vegetable slice thickness or olive sizes) Speed adjustable outlet band AISI 304 Stainless Steel FDA Approved Feeding Band Compressed Air-Inlet for optimum fire performance and LPG saving MADE IN TURKEY

View Machine

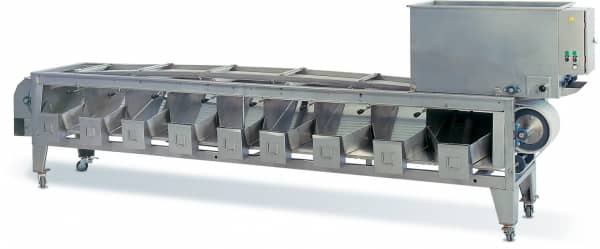

4-Meter 15-String Olive Sieving Machine

This machine classifies olives of different sizes. Since the spacing between the sieving compartments is adjustable, it is possible to obtain the desired caliber in the desired section. Olives are fed into the machine via a feeding conveyor, which is designed with speed control to ensure consistent and uniform feeding. The machine is constructed entirely from stainless steel and high-quality engineering plastics. It uses special braided strings to ensure more accurate calibration.

View Machine

4-Meter 25-String Olive Sieving Machine

This machine classifies olives of different sizes. Since the spacing between the sieving compartments is adjustable, it is possible to obtain the desired caliber in the desired section. Olives are fed into the machine via a feeding conveyor, which is designed with speed control to ensure consistent and uniform feeding. The machine is constructed entirely from stainless steel and high-quality engineering plastics. It uses special braided strings to ensure more accurate calibration.

View Machine

6-Meter Olive Sieving Machine

This machine classifies olives of different sizes. Since the spacing between the sieving compartments is adjustable, it is possible to obtain the desired caliber in the desired section. Olives are fed into the machine via a feeding conveyor, which is designed with speed control to ensure consistent and uniform feeding. The machine is constructed entirely from stainless steel and high-quality engineering plastics. It uses special braided strings to ensure more accurate calibration.

View Machine

10-Meter Olive Sieving Machine

This machine classifies olives of different sizes. Since the spacing between the sieving compartments is adjustable, it is possible to obtain the desired caliber in the desired section. Olives are fed into the machine via a feeding conveyor, which is designed with speed control to ensure consistent and uniform feeding. The machine is constructed entirely from stainless steel and high-quality engineering plastics. It uses special braided strings to ensure more accurate calibration.

View Machine

10-Meter 40-String Olive Sieving Machine

This machine classifies olives of different sizes. Since the spacing between the sieving compartments is adjustable, it is possible to obtain the desired caliber in the desired section. Olives are fed into the machine via a feeding conveyor, which is designed with speed control to ensure consistent and uniform feeding. The machine is constructed entirely from stainless steel and high-quality engineering plastics. It uses special braided strings to ensure more accurate calibration.

View Machine

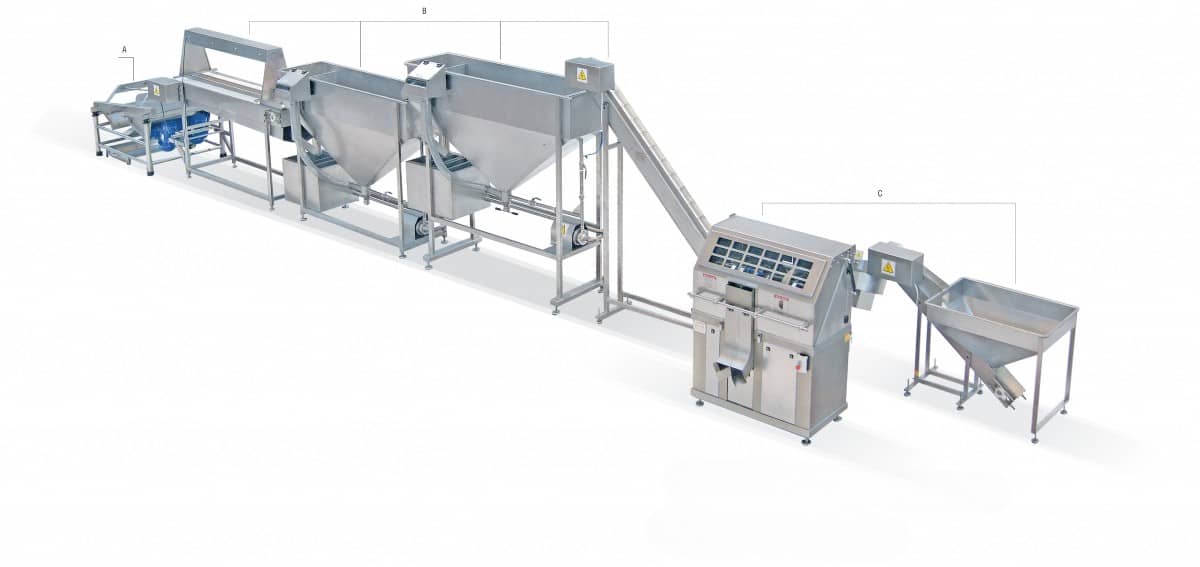

12-Blade Olive Pitting and Slicing Line with Densimeter and Vibrator

Olives poured onto the feeding conveyor are transferred to the slicing and pitting machine. This machine can either remove only the pits or, if desired, simultaneously slice the pitted olives. After processing, the sliced or pitted olives are carried via a transfer belt to the densimeter tank. In the densimeter, the olives are washed and separated from particles. Any olives that were not properly pitted are separated here using density differences. The olives exiting the densimeter move to the final inspection belt, where unsuitable products are manually sorted out. The selected olives then proceed to the vibrator, where they are rinsed and separated from small fragments and undesired particles—resulting in a clean, high-quality final product.

View Machine

Olive Pitting, Densimeter, Slicing, and Vibrator Line

Olives poured onto the feeding conveyor are transferred to the pitting machine at a speed synchronized with the machine’s operation. The pitted olives are then carried by a transfer belt to the densimeter tank, where any olives that still contain pits are separated. The olives are washed and cleared of any particles. After washing, they move onto the inspection belt, where defective or discolored olives are manually sorted out. The selected olives are then fed into the slicing machine via the same belt. After being properly sliced, the olives finally reach the vibrator unit. Here, broken pieces and small unwanted fragments are separated from the properly sliced olives, resulting in a clean and high-quality final product.

View Machine

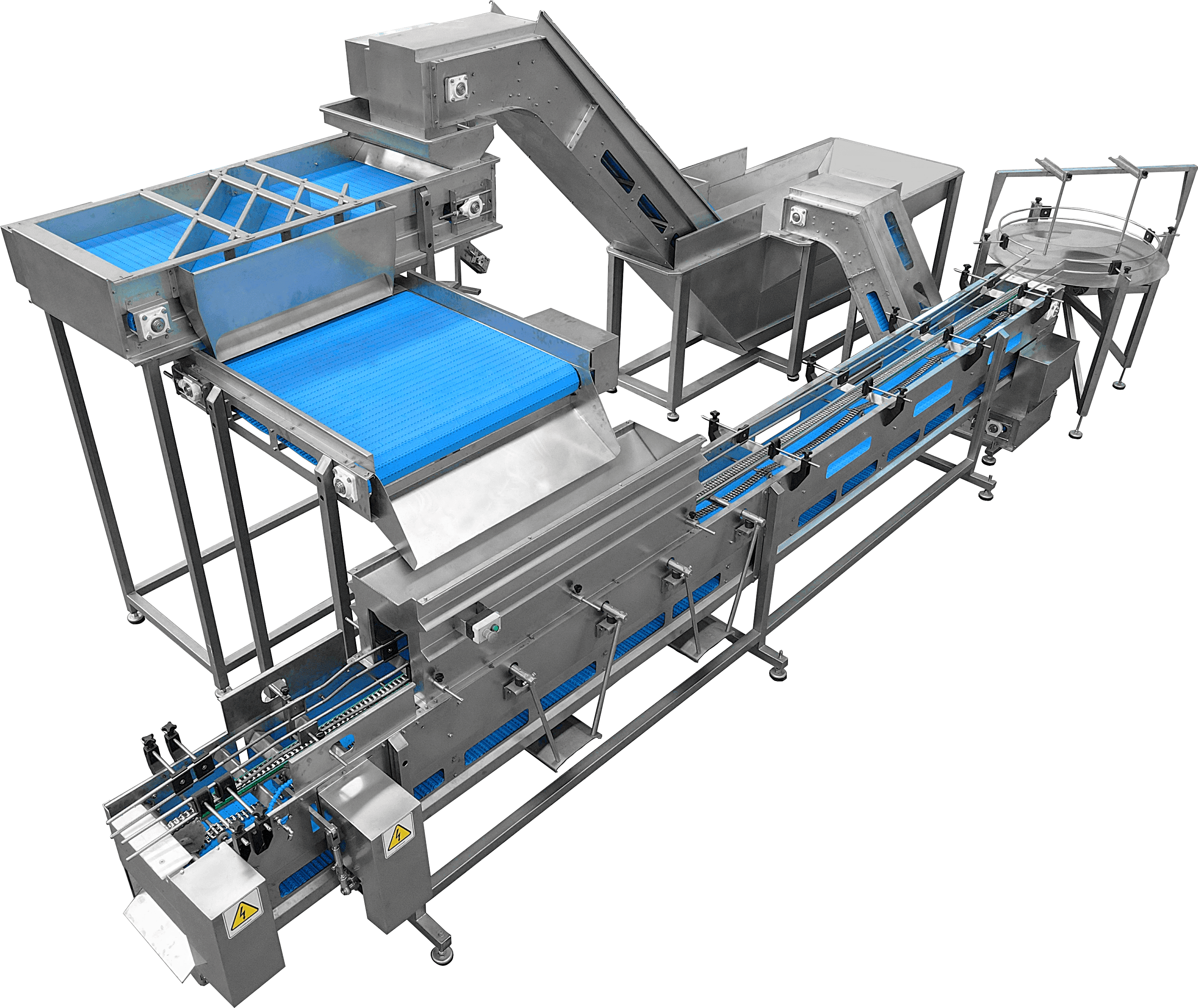

Olive Stem Removal, Sorting, and Sieving Line

Olives transferred by a transfer pump or drum emptying machine are fed into a bucket-type feeding conveyor and then delivered to the stem removal machine. In this unit, the olives are showered and washed, effectively removing stems and leaves. After stem removal, the olives move onto the sorting belt, where defective, discolored, or rotten olives are manually removed. The selected healthy olives are then transported by another bucket conveyor to the sieving machine. Graded olives are directed into drums via a high platform. At the end of the line, the olives are washed, destemmed, sorted, graded, and directly filled into drums—ready for shipment.

View Machine

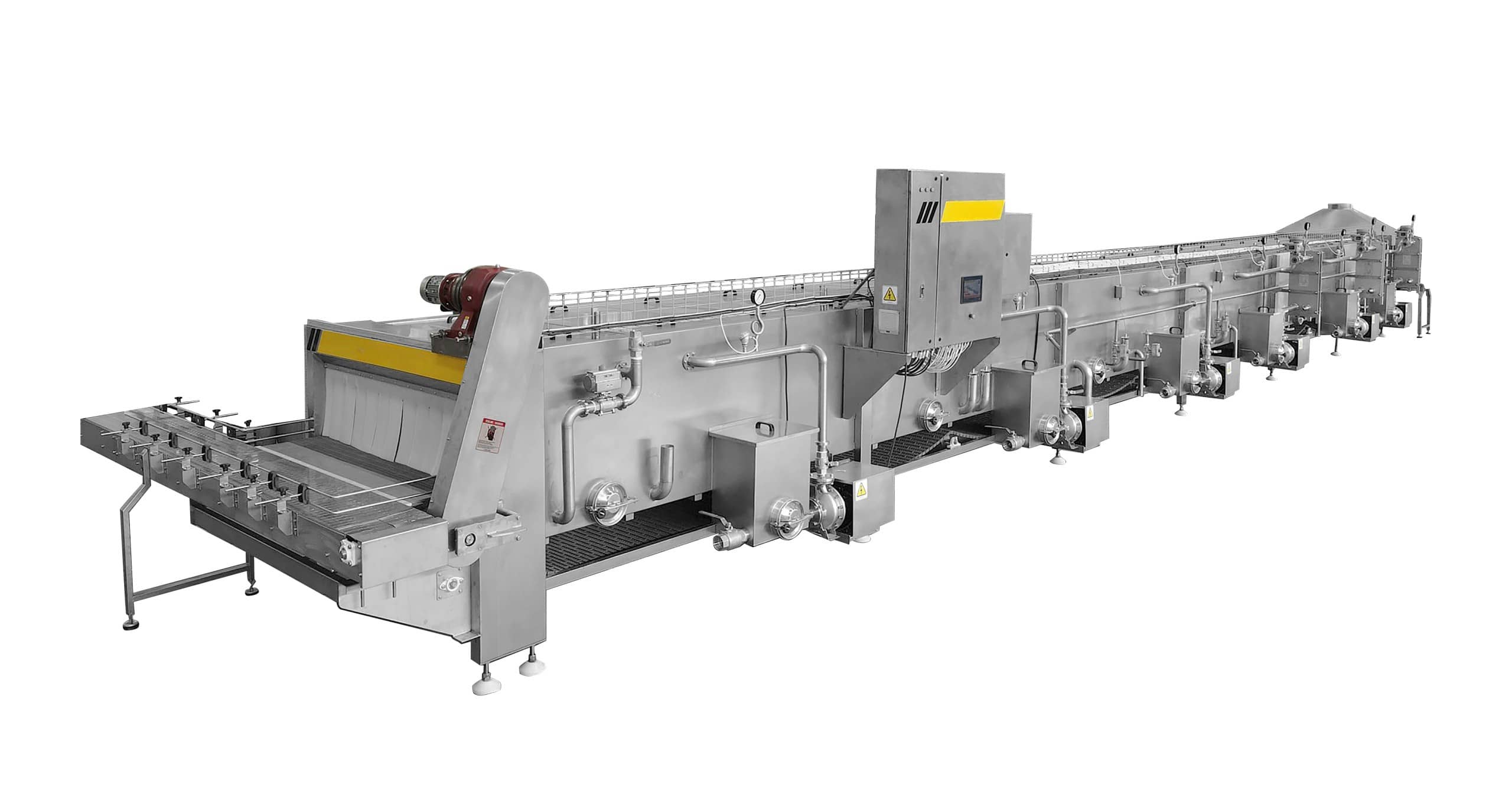

Gemlik Oiling Line

This line is designed for washing, sorting, surface drying, oiling, weight adjustment, and sealing of Gemlik olives. Olives poured into the wet elevator are first transferred to the pre-grading machine, where they are showered and washed, removing leaves and small particles. The olives then move to the sorting belt, where workers manually remove any unwanted, discolored, or soft olives via the waste channel. Accepted olives are carried to a small wet elevator, which transports them to the surface drying tunnel. Once fully dried, the olives are transferred to the elevator of the oiling machine. After being oiled, they are filled into tins, buckets, or other containers. During filling, a vibration system ensures the olives are properly settled in the packaging. The filled containers are then moved to a precision weighing station, where a worker adjusts the final weight using a sensitive scale. After weighing, the containers pass through an automatic liquid dosing station, where a pneumatic piston adds a specific amount of oil, vinegar, or other liquids as needed. Finally, the containers move to the capping machine, where pneumatic pistons seal the lids, making the product ready for shipment.

View Machine

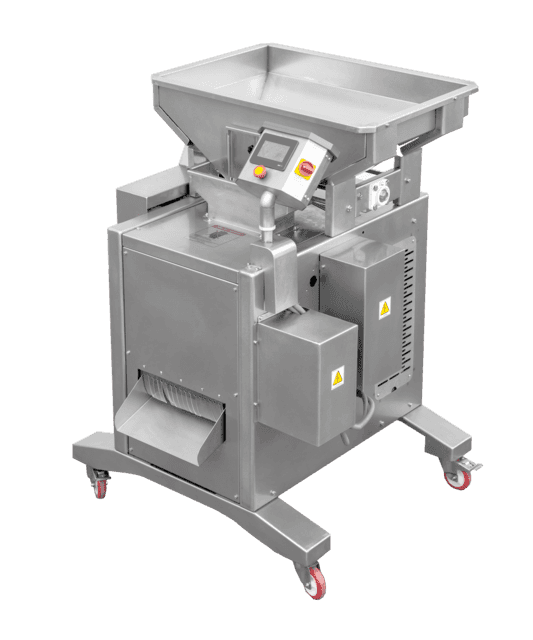

Olive Slicing Machine

The slicing machine is designed to cut various types of pitted olives into uniform shapes and thicknesses. Depending on the quality of the olives, up to 95% clean slicing efficiency can be achieved. The machine is engineered to prevent damage from unpitted olives by automatically separating them before they reach the cutting blades, ensuring they do not mix with properly sliced olives. Constructed entirely from stainless steel and equipped with special rubber-coated rollers, the machine is built to resist wear and provides a hygienic and user-friendly working environment.

View Machine

Densimeter Group

The Densimeter Group consists of three separate machines and operates in conjunction with the olive pitting machine.

View Machine

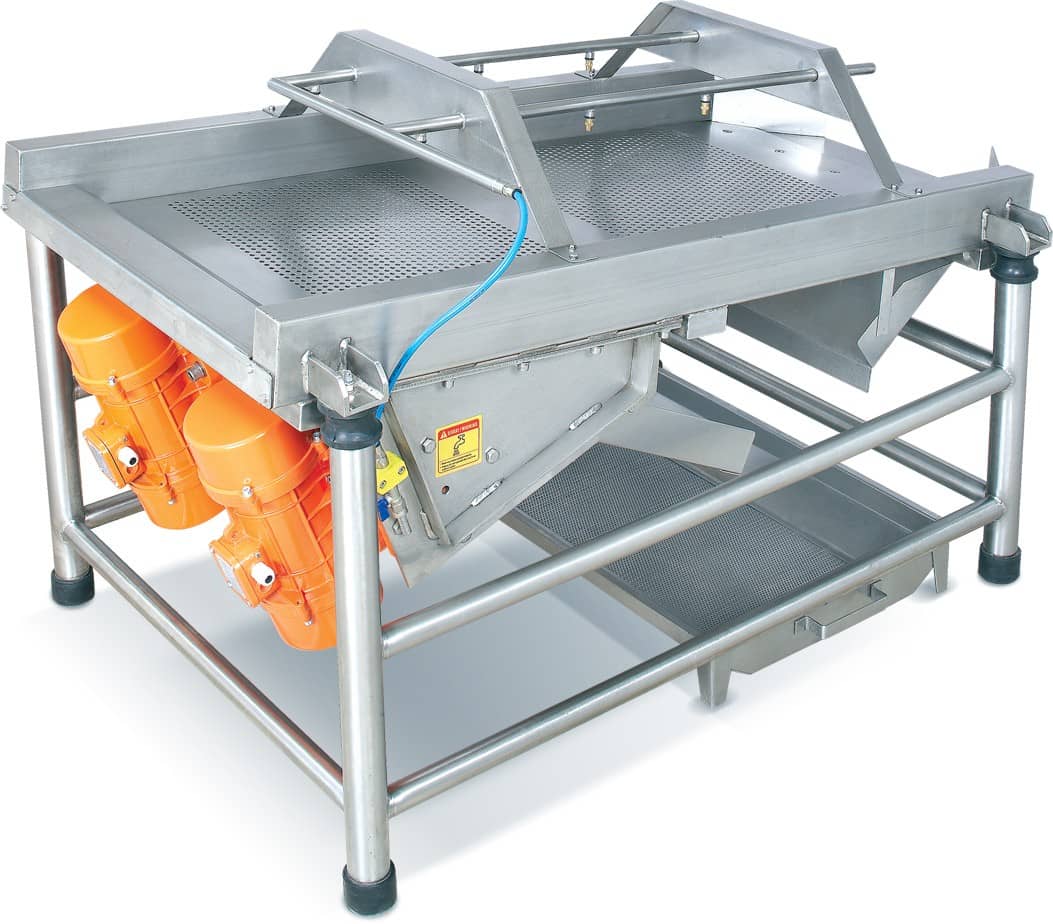

Vibrator

The vibrator machine is designed to separate small fragments and broken pieces from properly sliced olives. It can also be used for sieving various other products. Equipped with two vibration motors, the machine is constructed entirely from stainless steel. Thanks to its integrated rinsing system, even the smallest particles can be efficiently removed. The machine operates quietly and offers user-friendly functionality.

View Machine

Stemming Machine

This machine removes the stems and flowers of the goods such as olive, cherry, cucumber, etc. and is adjusted to the desired slope according to the dimensions of the goods. The stemming cylinders have a mixing system which makes the goods change position continuously and a shower unit. The machine is manufactured from stainless material including the stemming cylinders.

View Machine

Classical Olive Scratching Machine

This machine is designed to scratch olives with a high capacity. This machine user settings and maintenance of which is extremely easy thanks to its simple structure puts 2 scratches on one side and 3 to the other side of olive.

View Machine

Olive 3 Scratching Machine

Machine is designed to put three longitudinal scratches (two scratches on the top side and one on the bottom side) on olives. Thanks to its extra long walk, maximum positioning can be achieved so that longitudinal scratching is applied and it is seen as if hand-scratching. Machine is running with a rope-system. Blade deepness can be set at this machine which has electronic speed control system. Thanks to speed-controlled feeding conveyor a steady supply is maintained.

View Machine

Olive Crushing Machine

This machine is designed to break olives from the same point and with the same shape. Olives are carried to this machine with a feeding conveyor. Olives that are put into side position with private carrier rolls are put scratches at their middle here. Scratched olives are passed though crushing rollers and broken from the scratched points. Thus a standard crushing image is obtained and the core is prevented from falling. The machine is designed to be easily adjusted without using switches.

View Machine

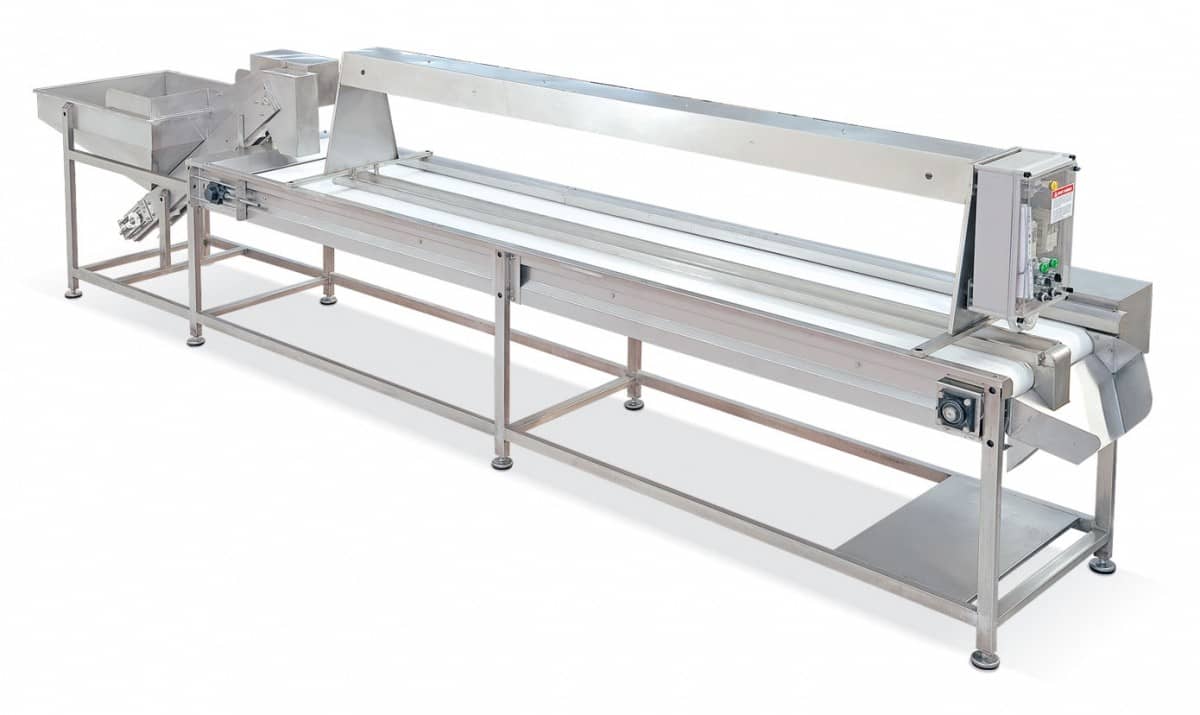

4 Meter Selection Band

This band on which various goods are selected is produced in different sizes according to customer needs. This machine consists of a line through which the selected goods are separated. Thanks to this line, inappropriate goods are separated from the appropriate ones at the end of the band. In order to provide a bright working environment, the machine has lightening fixture. However this lighting fixture is covered by a shelter so that the employers shall not be dazzled by the light. The machine has speed control and is supplied by a feed-band which has speed control. According to customer needs, it is produced with seats or seatless.

View Machine

6 Meter Selection Band

This band on which various goods are selected is produced in different sizes according to customer needs. This machine consists of a line through which the selected goods are separated. Thanks to this line, inappropriate goods are separated from the appropriate ones at the end of the band. In order to provide a bright working environment, the machine has lightening fixture. However this lighting fixture is covered by a shelter so that the employers shall not be dazzled by the light. The machine has speed control and is supplied by a feed-band which has speed control. According to customer needs, it is produced with seats or seatless.

View Machine

Pulper Machine

This machine separates the karnels and crusts of the goods such as olive, pepper, tomato, apple, apricot, etc and pulps the remaining part. These pulped goods become puree. The machine is manufactured from stainless material.

View Machine

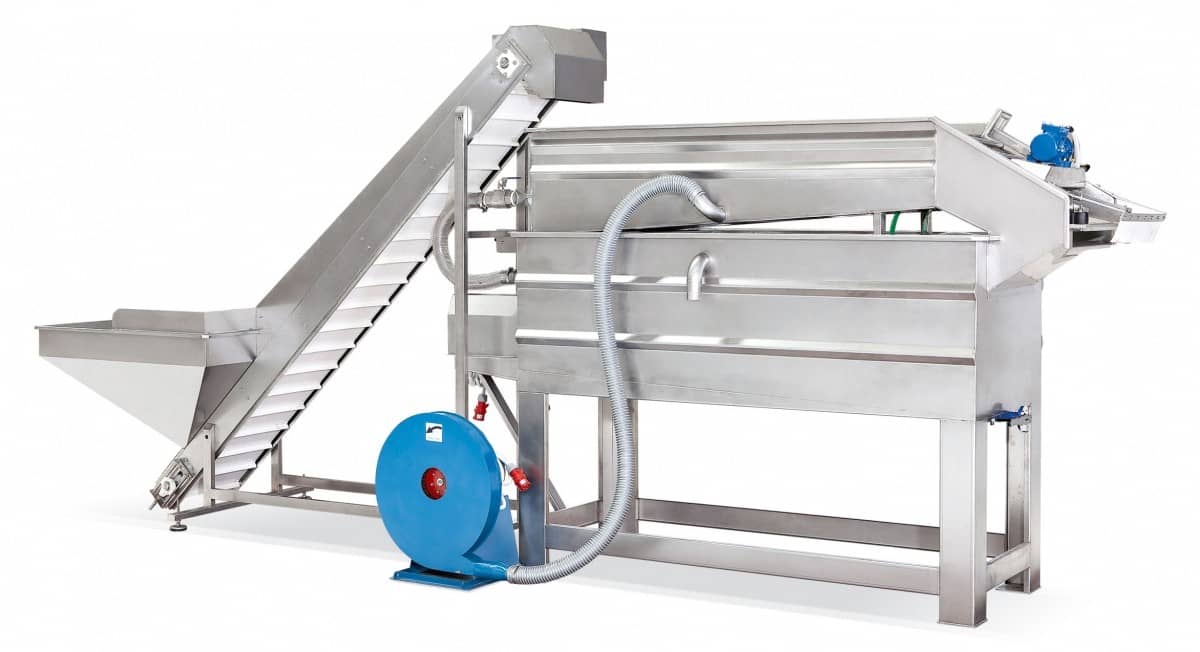

Olive Washing Machine

Olives pored into the machine with feeding conveyor are poured into the washing chamber here. Going forward by being washed with pump power, olives comes to the vibrated outlet hole and come clean out of the machine. Heavy metarials such as Stones etc. Are seperated by kneeling down here inside the machine. Water tank has dual stage ensure the pump operates properly and it has mud filter.

View Machine

Crate Empyting Machine

It is designed to discharge cases to the desired place and produced in different sizes according to the case size according to the case sizes and discharging heights. It has a stainless and hydraulic discharging system. Furthermore, it operates quietly and has and easy usage.

View Machine

Crate Washing Machine

This machine is used to wash crates that are used to carry olives and similar products. The machine has two separate water tanks and two separate water pumps. Water in each tanks can ne heated separately. Thanks to special nozzles crates are washed with showering. Showering water is circulated within the machine by filtering. At the final point, crates are showered with fresh water and cleaned completely.

View Machine

Labelling Machine

This machine is designed to label bottles, jars, etc. in different sizes at a high speed.

View Machine

Labelling Machine With Cold Glue

This machine which is designed to make labeling between diameters of 80 to 220, is suitable to attach a fully or half label onto the packaging.

View Machine

3″ Olive Transfer Pump

The machine transfers the granular products such as olive, cucumber, fish, etc. to any required place in the plant with the water containers where they exist. The products are by no means harmed during the transfer. All parts of the machine are made of stainless material.

View Machine

4″ Olive Transfer Pump

The machine transfers the granular products such as olive, cucumber, fish, etc. to any required place in the plant with the water containers where they exist. The products are by no means harmed during the transfer. All parts of the machine are made of stainless material.

View Machine

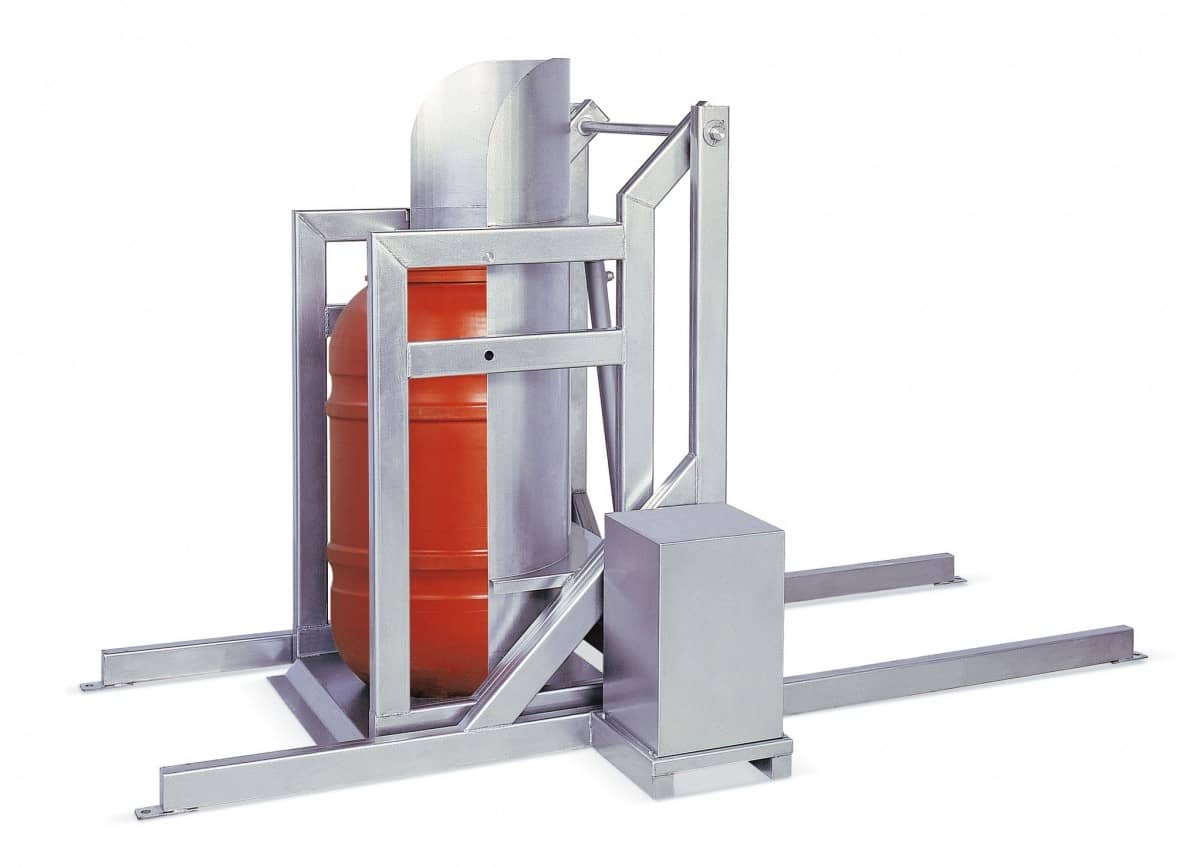

Barrel Emptying Machine

It is designed to empty barrels to various places where required. The machine is completely made of stainless material and involves hydraulic turning system. It is quite noiseless and practical.

View Machine

Vibrating Filling Machine

Used to fill tins/jars with table olives.

View Machine

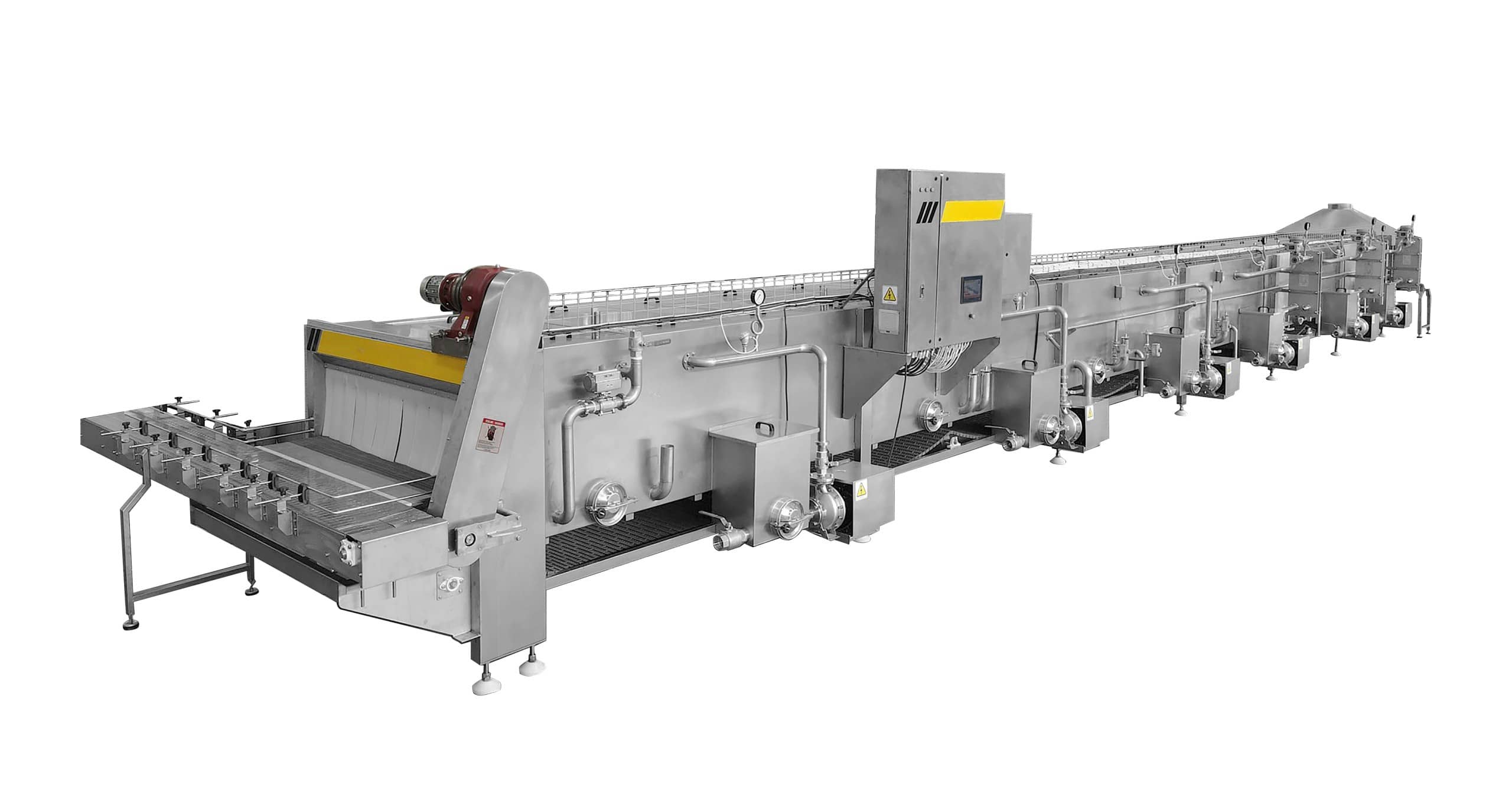

12 Meter Pasteurization Tunnel

Pasteurization is a heating method in the food industry to purify nutrients from disease-causing microorganisms.

View Machine

18 Meter Pasteurization Tunnel

Pasteurization is a heating method in the food industry to purify nutrients from disease-causing microorganisms.

View Machine